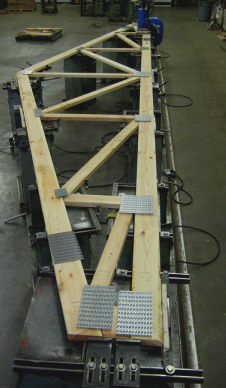

Fairbanks Truss uses Douglas Fir MSR (Machine Stress Rated) lumber for all cord and web members. We have found that this produces a superior product over SPF (Spruce Pine Fir) which is more common in the industry. Our lumber comes from Vaagen Bros., a mill in eastern Washington State that has supplied us for many years.

Fairbanks Truss uses Douglas Fir MSR (Machine Stress Rated) lumber for all cord and web members. We have found that this produces a superior product over SPF (Spruce Pine Fir) which is more common in the industry. Our lumber comes from Vaagen Bros., a mill in eastern Washington State that has supplied us for many years.

Cutting is accomplished with our 5- blade Mitek component saw. This saw produces clean accurate cuts for all our cord and web members. Trusses are assembled on one of our two production lines. We use a Auto 8 table press built by Pacific Automation with custom built jigging for smaller trusses such as hips and jacks. This is a precision machine that allows us to accurately build trusses to exact dimensions. Larger trusses are built on a Mark 8 mono press by Hydro-Air. This press utilizes magnetic pedestal stands at each joint or press point with uni-strut jigging.

We retain our production employees long term. This means your trusses are built by individuals who have 10-20 years experience working in this shop.

Fairbanks Truss Co. is a member of the Truss Plate Institute (TPI), a third party quality assurance inspection agency. What does this mean to the consumer? Your trusses are built and inspected to a consistent industry standard. The TPI inspection program is a dynamic process of continual inspections leading to improved fabrication methods and more selective use of materials. This program helps our truss plant consistantly exceed the quality standard for wood truss manufacturing.